86-571-85360681

Floor 21, Building 2, No. 868, Shixin North Rd, Xiaoshan District, Hangzhou, Zhejiang, China (Mainland)

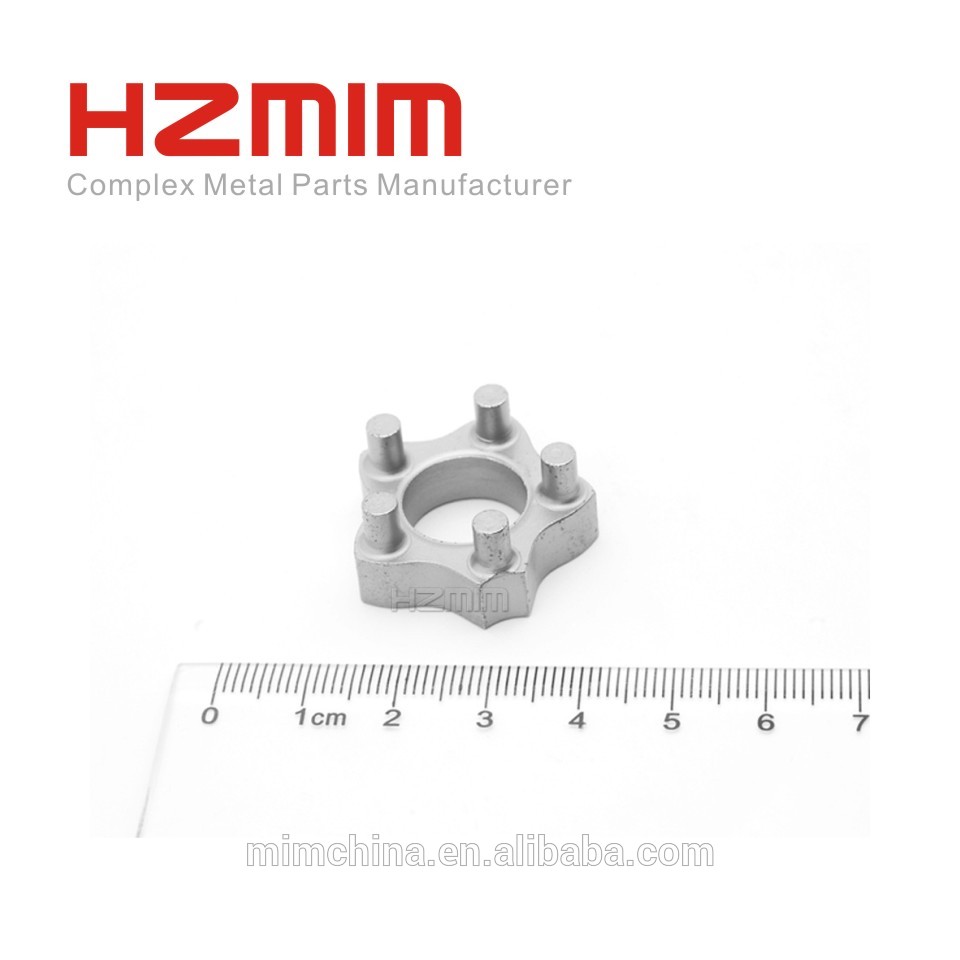

machinery industrial parts and tools, oem central machinery parts by MIM (metal injection molding)

1 | material available | 1.Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS4203. 2.Brass:C36000 ( C26800), C37700 ( HPb59), C38500(HPb58), C27200(CuZn37),C28000(CuZn40) 3.Iron:1213,12L14,1215 4.Aluminum:Al6061,Al6063 5.OEM according to your request |

| 2 | processing method | metal injection molding, CNC machining, tuning, milling, drilling, grinding, broaching, weilding and assembly. |

| 3 | surface finish | polishing, sandbster, plating, pvd, chrome plating, yellow passivation, gold passivation, galvanizing, etc.. |

| 4 | tolerance | ±0.02 |

5 | QC | 100% |

| 6 | Certificate | ISO9001:2008 |

| 7 | Size | ad per your drawings. |

| 8 | Design | 3D design available. |

MIM materials have had their chemistries modified in order to withstand the complex metal injection molding process.

There are a wide variety of materials available for metal injection molding, and they generally fall into four categories:

Ferrous alloys, Tungsten alloys, Hard materials, Special materials.

| Ferrous alloys: | steels | stainless steels | tool steels | iron-nickel magnetic alloys | specialty ferrous alloys (Invar and Kovar) |

| Tungsten alloys: | tungsten heavy alloys | tungsten-copper | |||

| Hard materials: | cobalt-chromium | cemented carbides (WC-Co) | cermets (Fe-TiC) | ||

| Special materials: | aluminum | precious metals | titanium alloys | nickel | nickel-base super alloys |

| molybdenum | molybdenum-copper | particulate composites | |||

| Other specific materials: | |||||

| stainless steel: | 316L Stainless steel | 17-4PH stainless steel | 420 stainless steel | 440C stainless steel | 430/303/304 |

| Low alloy steel: | Fe-2Ni low alloy steel | Fe-8Ni |

At HZMIM, we specialize in stainless steel, and low alloy steel materials for MIM. We can also process Cobalt Chrome (F-75) and other specialty or custom materials.

Don’t worry if you don’t see your material of choice, we can manufacture your precision component using many other materials.

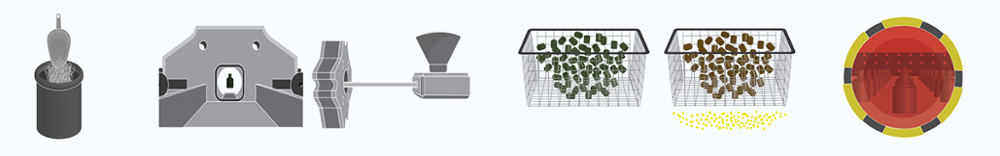

Once the proper material is selected, the key steps for the MIM process are as follows:

Step 1: Feedstock – very fine metal powders—usually <15 microns—are mixed with a primary paraffin material and a secondary thermoplastic polymer resulting in a 95-100 percent theoretical density and much closer tolerances.

Step 2: Molding – the feedstock is fed into our multi-slide MIM machinery or our conventional molding equipment, then heated and injected into a cold cavity under high pressure. Once it is removed, the component is referred to as a “green part.”

Step 3: Debinding – the “green part” is then put through a controlled process called debinding that removes the binder and prepares the part for the final step. Once the debinding is complete, the component is referred to as “brown.”

Step 4: Sintering – the “brown” part is held together by a small amount of binder and is still fragile. During sintering temperatures reach near the melting point of the material. Sintering eliminates the remaining binder and gives the part its final geometry and strength. The entire sintering process takes 15 to 20 hours.

MIM Tooling

When choosing a MIM manufacturer you want to make sure that whatever tooling process you choose delivers consistent parts efficiently and repeatedly. At HZMIM we offer:

Conventional tooling – comes in single cavities, meaning only one part is created per cycle. Our conventional tooling process is suited to larger parts and is designed to offer you efficiency in production and lower costs.

Multi-slide tooling – uses four or more perpendicular slides enabling very complex and accurate casting. In some cases, we use up to six slides, with angles other than 90 degrees. This new process helps meet tighter tolerances and offers better part-to-part consistency.

Heat Treating for MIM Components

MIM materials may be heat treated to increase strength, hardness, and wear resistance. The degree of hardening is determined by the percentage of carbon, alloying elements, and residual porosity of the component. Heat treated parts are given the ultimate tensile strength. To ensure optimum strength and durability, tempering or stress relief is required after quenching.

Calibration after Sintering

After your components are completely rid of all binding material, it may need to be calibrated. Calibration can include these three processes:

Coining

Sizing

Straightening

During the sintering process, parts can be distorted, and start to sag or drag. The three processes above correct these issues and return the part to its original design. Some manufacturers will ship your components elsewhere for calibration, however HZMIM does this process in-house.

Q1. What's your MOQ? / Could you accept small orders?

A: For OEM order (customized logo etc..), difference items have different MOQ. / We can accept small orders.

Q2. Could I get some samples before make order?

A: Yes, we can arrange sample for your quality checking, please kindly contact us for details.

Q3. You are factory or trade company?

A: We are professional factory.

Q4. Can i visit your factory?

A: Yes, you are always welcome to our factory.

Q5. How can I pay you?

A: After you confirm our PI, you could pay by T/T and Credit Card, PayPal, Western Union, which are the most usual ways we are using.

Q6. How do you check all the goods in the production line?

A: We have inspection and finished product inspection. We check the goods when they go into next production procedure. All our parts are inspected with 100% QC.

For our hot sell products with custom brand, we can accept a mini order. It is subjected to our customized availability and we can arrange the delivery within 20 to 30 days after the order is placed.

No matter you are a wholesaler or you may have your own solid store or e-shop, just feel free to contact us for our latest hot sell product catalogue.

Contact Us: